Rigid polyurethane (PUR) and polyisocyanurate (PIR) insulation products are highly effective, lightweight and many have the ability to bond to most materials. Their excellent thermal conductivity and high strength to weight ratio, combined with great manufacturing versatility provides a range of products. As a result, PIR/PUR insulation products are the natural choice for most construction insulation applications. PIR foam is chemically and thermally more stable: breakdown of isocyanurate bonds is reported to start above 200°C, compared with urethane at 100 to 110°C.

RIGID PUR insulation products are made by reacting a liquid polyol component with a liquid polymeric isocyanate, Methylene Diphenyl di-Isocyanate (MDI), component in the presence of a blowing agent and other additives. The mixed components then react exothermally to form a rigid thermosetting polymer and since the blowing agent evaporates during this exothermic reaction a rigid closed cell low density insulation product is created. Excellent insulation is achieved because the gas trapped within the closed cell structure has a very low thermal conductivity and there is minimal heat conduction through the solid cell walls due to the low density, where approximately 97% of the volume of the foam is trapped gas.

RIGID PIR differs from PUR in that it is produced using an excess of the MDI component. In the presence of an appropriate catalyst the excess MDI reacts with itself to form isocyanurate which is characterised by greater heat stability. The resultant PIR insulation products exhibit increased fire performance and reduced combustibility and higher working temperature limits compared to PUR and when incorporated into building products, can meet some of the most demanding fire performance requirements such as those currently stipulated for some applications by the insurance industry.

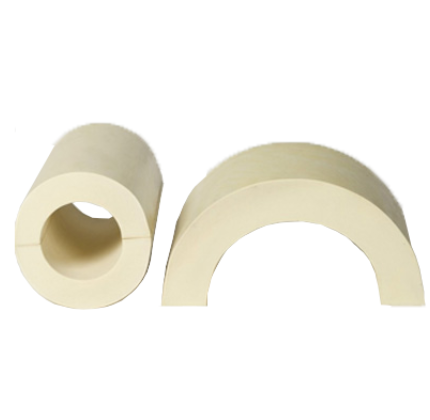

The material is available in sectional pipe covering and fittings, board segments for equipment and curved segments for tank wall and head applications. The density of rigid polyurethane foam (PUR/PIR) used for thermal insulation in buildings normally ranges between 30 kg/m³ and 45 kg/m³. However, it can reach 100 kg/m³ for some applications. For special applications that are subject to extreme mechanical loads, the density of the rigid polyurethane foam (PUR/PIR) can be increased to 700 kg/m³.

In-situ Foams In addition to factory made polyurethane rigid foams (PUR/PIR), in-situ foams are also used in building. They are produced with state-of-the-art equipment “in situ” on the building site itself. In-situ foams are mainly used for technical insulation applications. The in-situ foam is sprayed onto the desired surface or poured into moulds, producing a seamless structure.

- Thermo-setting polymers

- Chemically inert

- Biologically inert

- Good and versatile mechanical properties

- High thermal and electric insulator

- Excellent adhesion