Other Insulation Ancillary Materials

INSULATION FINISH (Ancillary): Materials Sealant

All circumferential and longitudinal joints are sealed with Sealant seals the joints of cellular glass, PIR, polystyrene and other insulations against the entrance of moisture. When used as a bedding compound on iron or steel surfaces and as a joint sealant, Its provides additional protection to the blocks of insulation. Damage to the insulation due to migration of moisture is minimized. Its butyl rubber-based product used as a vapor barrier sealant in the joints of cellular glass, polyisocyanurate (PIR), urethane and phenolic foam board stock insulations.

Primary Vapour Barrier

Secondary Vapour Barrier

Aluminum Foil and TIC Bwrap PB201 is a Self‐Adhesive Polymer Membrane product as the primary vapour or Secondary Vapour Barrier which is laminated with a functional film. Its prevents water leakage on the insulation materials under outdoor ambient. Heavy duty performance is suitable to use of water and vapour stop.

Its does not require drying time, and the single layer’s installation meets the specific water & vapour permeance. Consequently. TIC Bwrap PB201 is qualified as CLASS A by a flame resistance test standard ASTM E 84, and M1 grade by standard NF P 92‐501.

Cryogenic Coating

Insulation Jacketing Materials

Insulation jacketing consists of an outer covering that is wrapped around tubing or pipe insulation to protect the insulation from moisture, wear and mechanical damage. The jacket also serves to provide support for the insulation and establish the system emissivity and appearance. Insulation jacketing plays an important role in the efficiency of the insulation.

Metal jackets

Metal jackets are manufactured from metal sheets such as aluminum, stainless steel, coated steel, aluminized steel. This protects the metal from moisture corrosion.

Aluminum sheets

Aluminum sheets are widely used in fabricating metal insulation jacketing. Aluminum has light weight and good corrosion resistance. The disadvantage of aluminum is that is has poor durability when exposed to heat. The material can have a smooth, embossed and corrugated surface finish. Smooth finishes have a more attractive and easier to clean surface, however, they show surface wear. Embossed finishes do not show surfaces damages but they do hold contamination easier than smooth surfaces. Corrugated surfaces are available in a variety of sizes and are stiffer than other jacket materials. The disadvantage of a corrugated surface is that water can collect on the top surface which can then penetrate into the insulation.

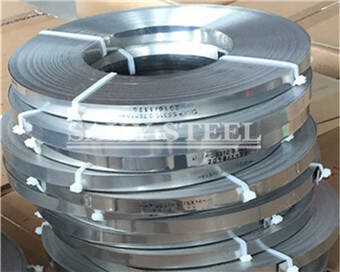

Stainless Steel Jacketing

Stainless steel jacketing is often used in chemical plants to protect the underlying insulation and pipe from the corrosive fumes and leaking chemicals and other environmental conditions. This material is also used when there is a potential for fire because it melts at a much higher temperature and will remain in place much longer than aluminum. Stainless steel is more expensive than aluminum but it provides superior protection against fire and corrosion and is therefore the most commonly selected insulation jacketing material.

Band: SS304, SS316

SS304 Wires

SS Wing seal

SS Screws